Technology

AI-Robotics

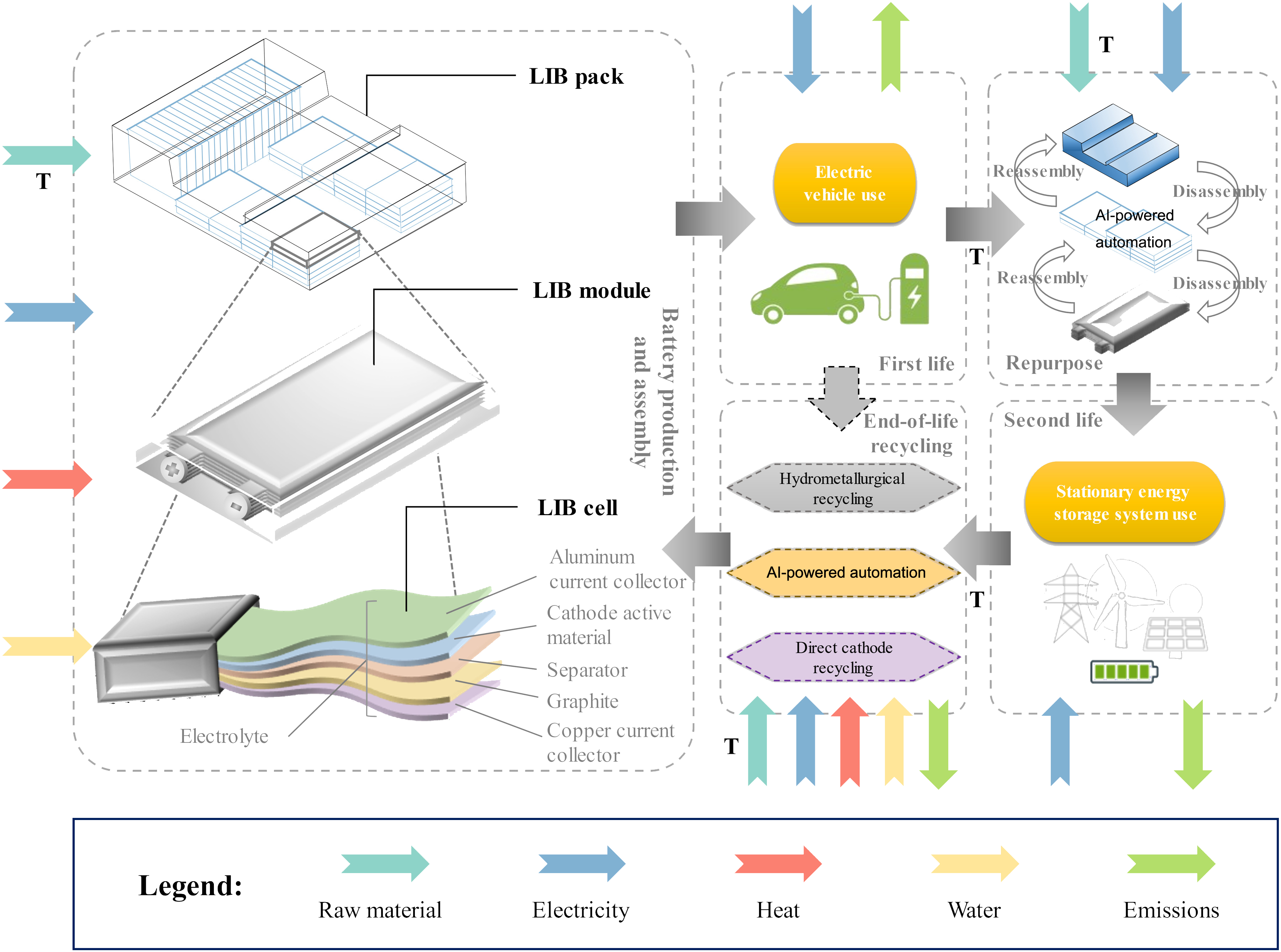

Digital and AI technology are used in sorting, testing, robotic disassembly and process automation, for better perfomance.

View ServiceDirect Recycling

Process for unusable battery cell, consumer waste, and manufacture scrap. The products are high-quality cathode and black mass.

View ServiceSecond Use

Repurposed used battery for applications such as distributed solar battery storage or telecom backup power etc.

View ServiceAI-Robotics

Visual pre-screening, quick testing and battery life prediction, smart-sorting, robotic disassembly and reverse supplychain efficiency

01

Pre-screen Quick Test

to establish the battery assessment and logistics.

02

Smart

Sorting

as decision-making using sensor and machine learning.

03

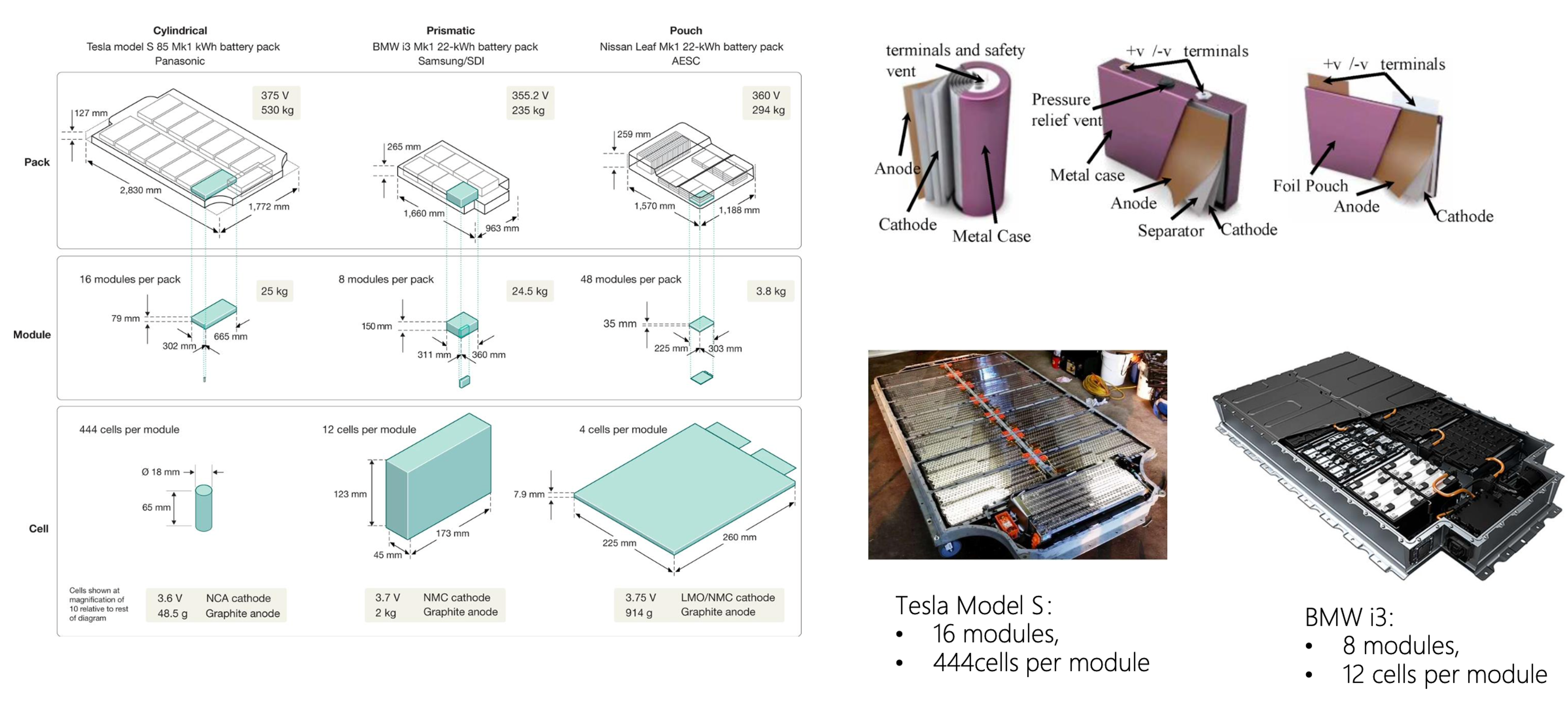

Robotic Disassembly

for fast battery handling and better part value recovery.

04

Operation Efficiency

for recycle process as well as overall reverse supplychain.

Technology Innovation

-

Battery health prediction modeling: Combined math model and MLP algorithm for quick SOC/SOH analysis and prediction.

-

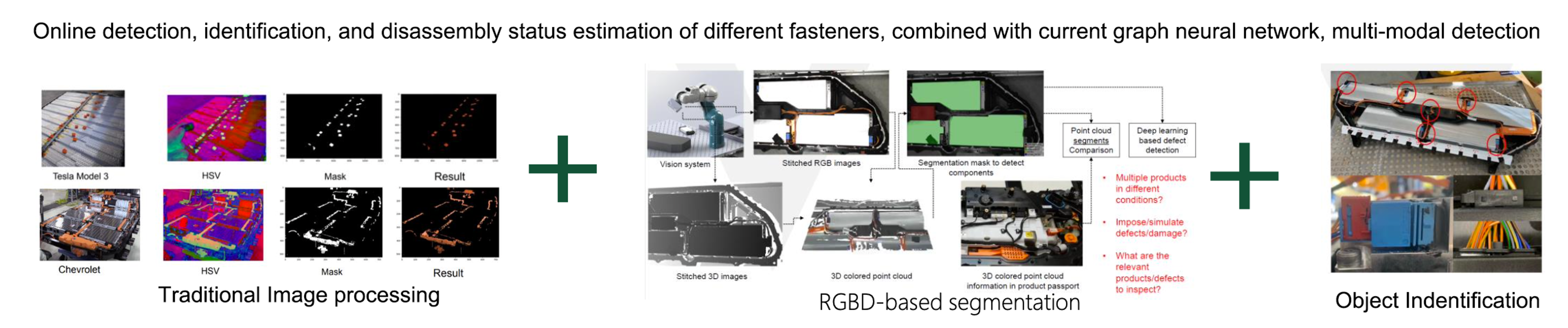

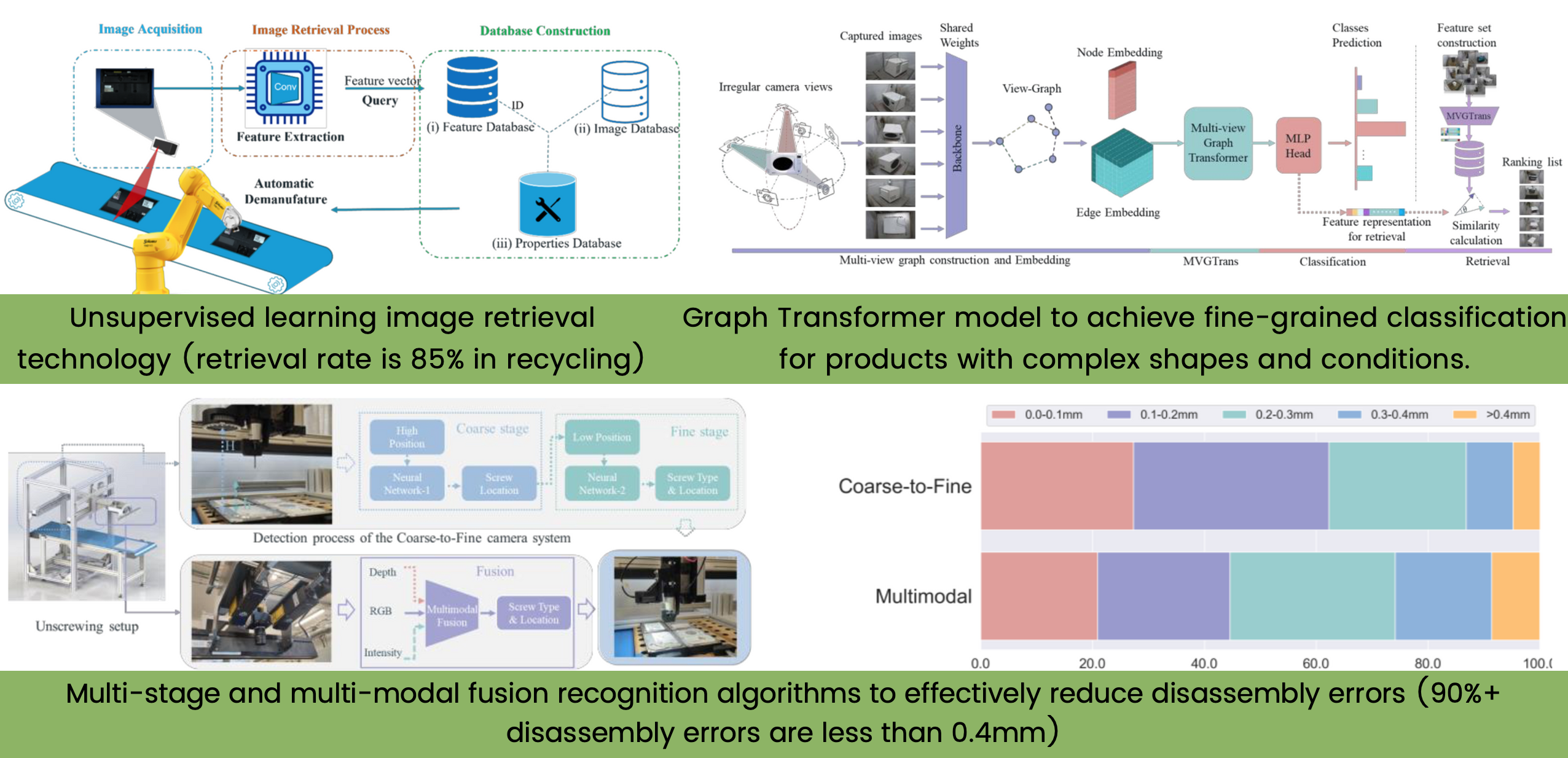

Smart pre-screening and sorting system: A quick labeling, screening and sorting system based on computer vision, machine learning and predictive algorithm.

-

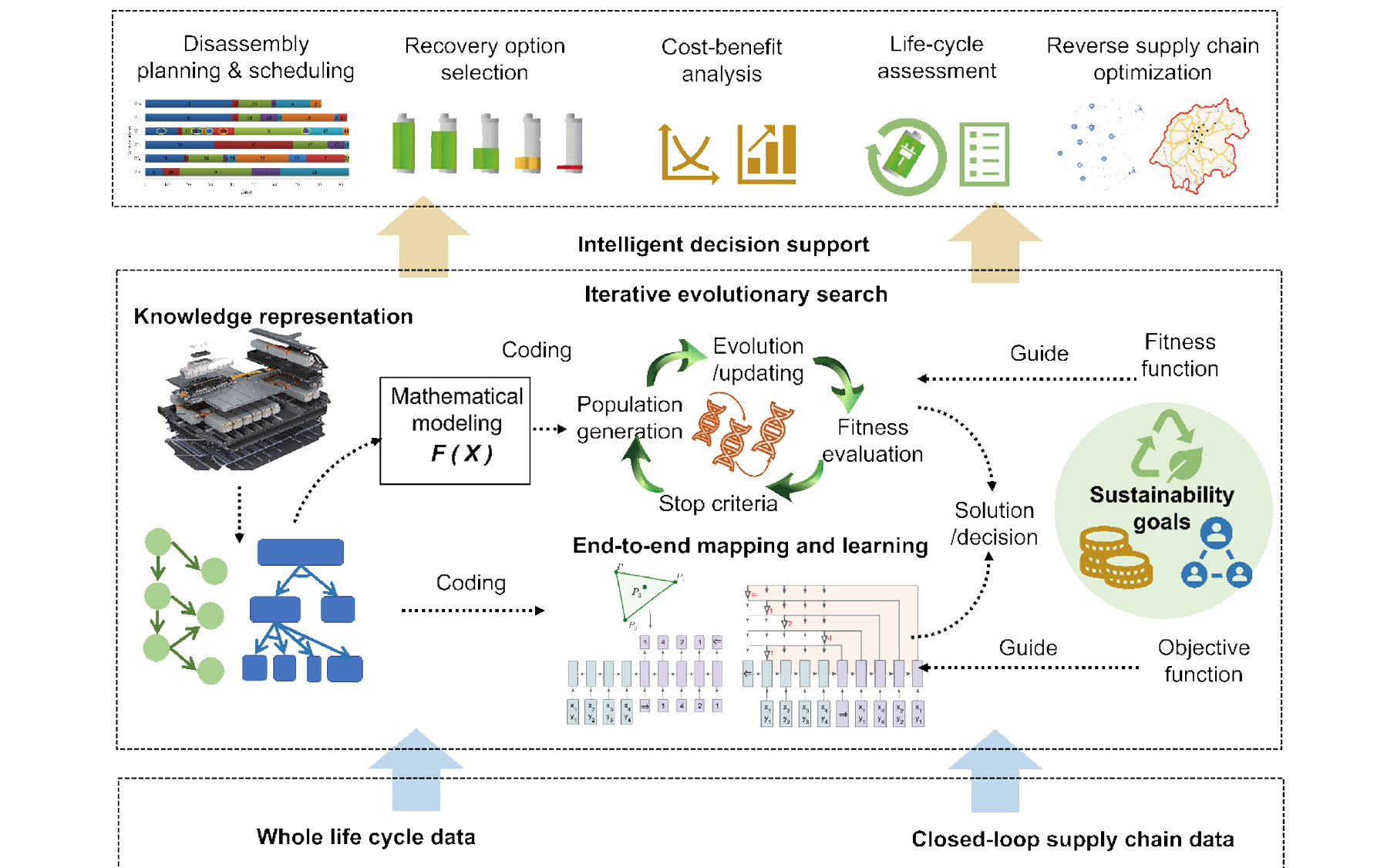

Intelligent disassembly planning system: A disassembly decision planning and scheduling system is built on battery knowledge graph, with the consideration of recovery option, cost-benefits analysis, lifecycle assessment and carbon footprint tracking, reverse supply chain decision.

-

Robot flexible control unit: A self-learning collaborative and flexible robot control unit is developed to identify defect part, optimize disassembly operation, detect disassembly failure, and predict disassembly effects.

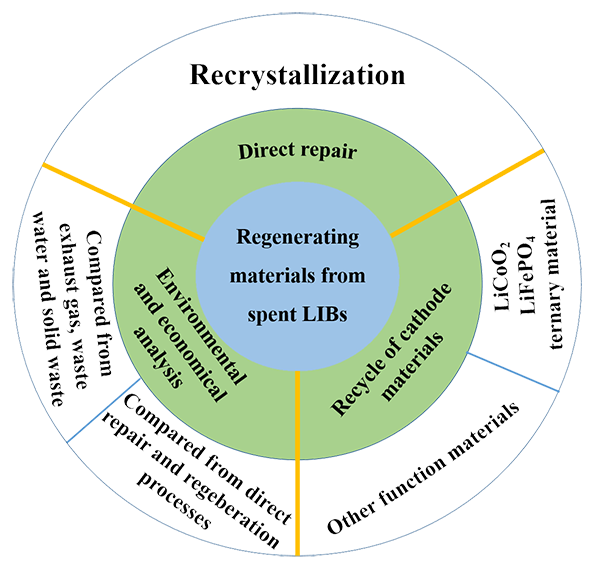

Direct Cathode Regeneration

-

Proprietary Separation

Proper feedstock are shred into power and separated into different type of material.

-

Material Purification

Cathode materials go to further treatment and are purified to certain level.

-

Recrystalization

Purified cathode material are added more virgin material and go through recrystalization process, to become battery grade material.

Direct Recycling

-

Smart Sorting

After disassembly and dismantle, sensors and machine learning software are used to screen physical and chemical features of the battery for automatic sorting.

-

Direct Cathode Regeneration

Cathode materials are separated using proprietary method, and regenerated to battery grade.

-

High-quality Black Mass

Mixed feedstock and manufacture scrap are processed into high-quality black mass materials.