Service Details

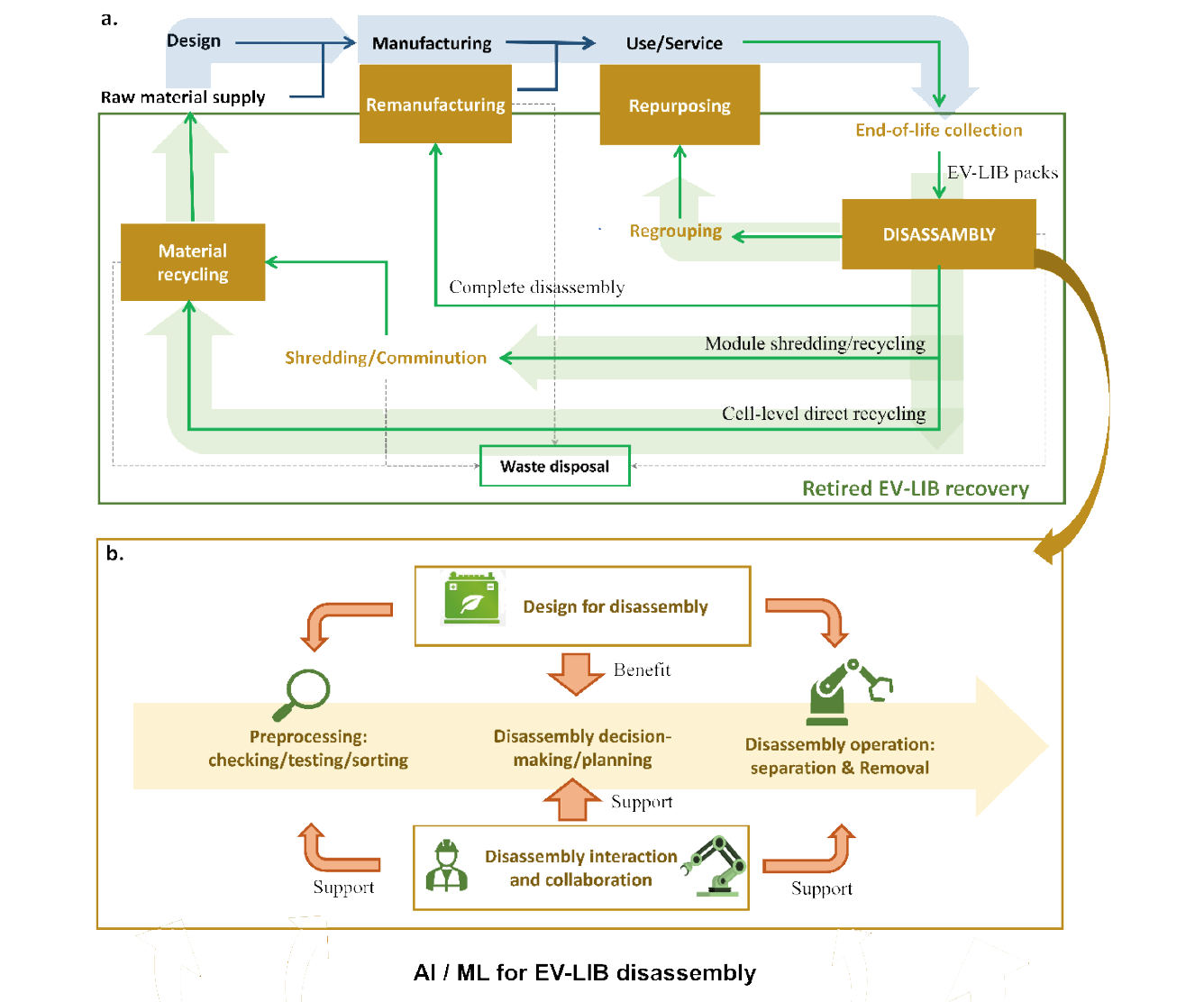

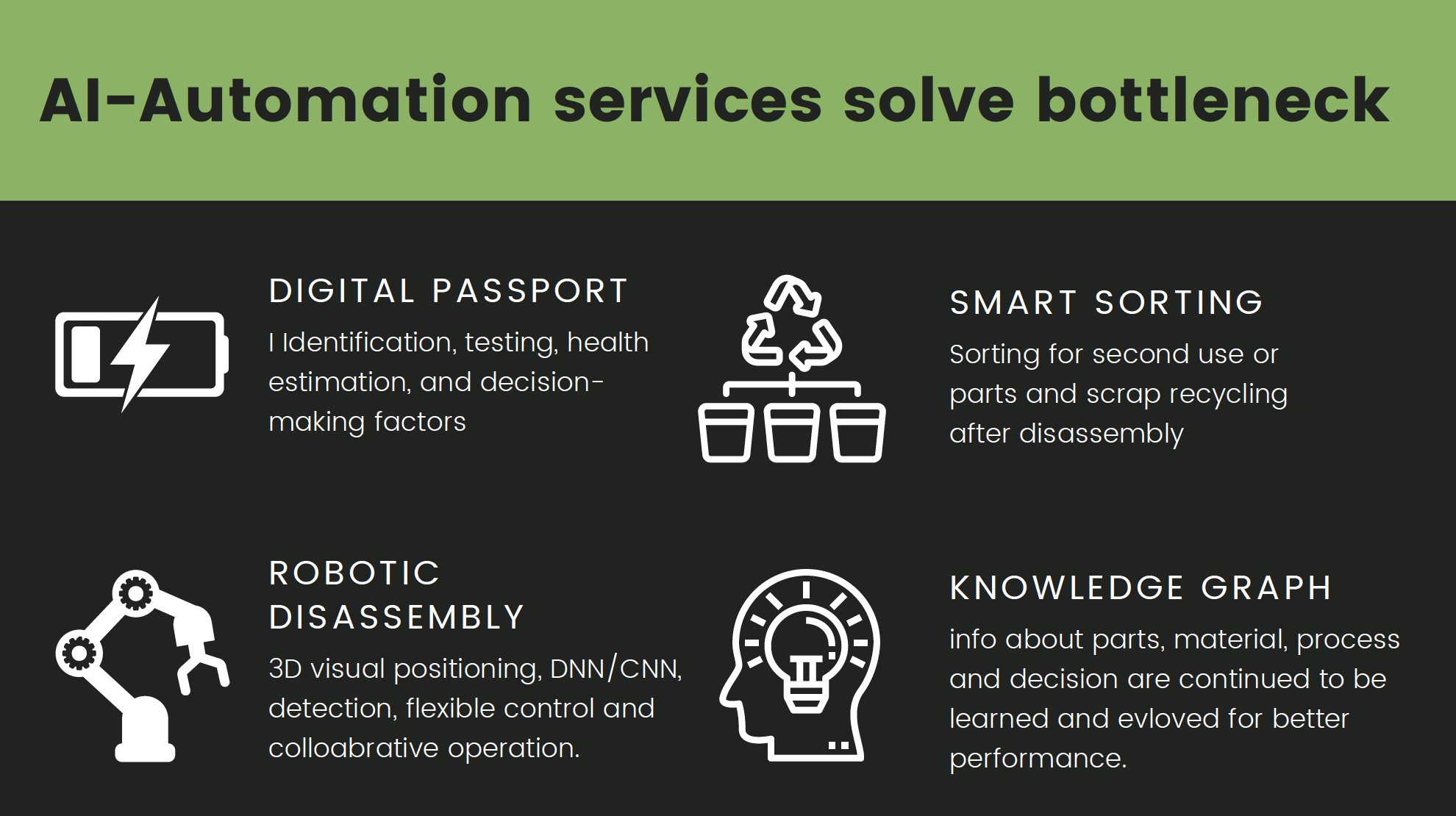

We airm to build modulated smart sorting and robotic disassembly plant (5000 ton/y) together with partners and customers. We use technology with computer vision, machine learning, DNN and flexible robotic control, and establish battery knowleadge graph system.

Service Included

-

We help our partner to evaluate their typical waste stream and provide proper sorting and disssembly solution.

-

Circunar intelligence service as the pre-treatment.

-

Qualified battery pack are grouped and sent to second use.

-

Unqualified battery pack are disassembled and good & acceptable battery cell and parts are detected and sent to repurpose or refurbish use.

-

Remaining feedstock will be sent to direct recycling.

Service Features

Sensors and AI-powered software are used to detect the physical and chemical features of the battery. The feedstock is analyzed in real-time and sorted with high accuracy and speed. The scrap after disassembly will also be sorted automatically for further processing.

More Technical details can be found as following.